The port of Zhangjiagang has put into use the country's first intelligent monitoring and control system for port dust. With the help of laser radar technology, no manual operation is required to suppress dust from the source.

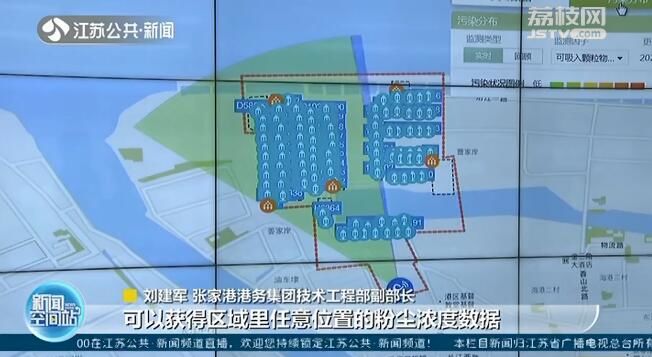

At a terminal of Zhangjiagang Port Group, an early warning message popped up on the large screen of the command center of the bulk loading and unloading area, indicating that the PM10 density in this area had exceeded the set value.

After the warning was issued, the two spray guns in the area were automatically turned on to spray and remove dust in a matter of 30 seconds.

Liu Jianjun, Deputy Director of Technical Engineering, Zhangjiagang Port Group

The system has five dust monitors and a set of dust laser radar which can obtain dust concentration data at any location in the area.

In order to avoid occlusion, the laser radar is installed at the highest point of the 30-meter dock.

However, limited by the range, the radar can only monitor the spatial distribution of the dust concentration on the horizontal plane where the highest point is located, which hinders the detection of dust concentration on the ground.

The Port Group has therefore developed a space tracking model for particulate matter to achieve precise positioning.

Liu Jianjun, Deputy Director of Technical Engineering, Zhangjiagang Port Group

The cargo pile is only 10 meters to 30 meters high there will be a diffusion process.We used intelligent algorithms and self-learning techniques to detect the source of the dust explosion by combing with meteorological data and wind direction and wind speed.

On the other end of the monitoring system is the intelligent sprinkler linkage control system. At present, the Port Group has installed 129 intelligent water spray guns in the 158 thousand-square-meter bulk cargo terminal area, spraying dust through targeted intelligent control, which can save more than 1 million yuan in comprehensive cost each year.

(Source:ourjiangsu.com)