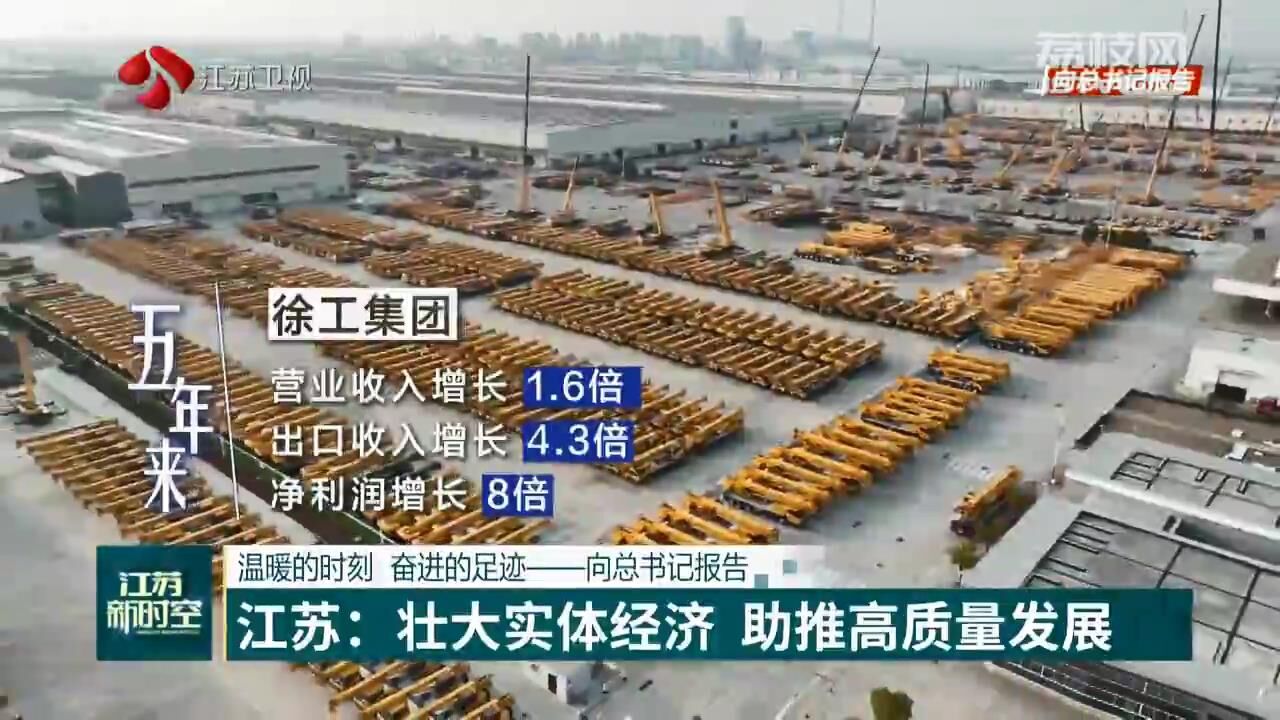

East China’s Jiangsu province has made unremitting efforts to strengthen the real economy for the promotion of high-quality development. Let’s take a close look.

Shortly after the closing of the 19th National Congress of the Communist Party of China, General Secretary Xi Jinping visited Xuzhou Construction Machinery Group in his first inspection tour to local regions.

Li Changqing, a researcher at XCMG, recalled that the General Secretary sat in the cab of a super-large all-terrain crane and made detailed inquiry about the performance, output and price of the crane. The General Secretary stressed that the equipment manufacturing industry is the backbone of the manufacturing industry.

"At that time, everyone at the scene was very excited. The message of the General Secretary further strengthened our determination to tackle the core technology of original creation. In recent years our R&D investment has been maintained at more than 5% and nearly 1000 core basic parts manufacturing technologies have been conquered so far. We are proud to say that every two years we will produce a crane product with the strongest lifting capacity in the world, which has always maintained the world's top record," said Li Changqing, Director of the General Office of the All-terrain Crane Research Institute of Xuzhou Heavy Machinery Co., Ltd. of XCMG.

To strengthen the real economy, in addition to achieving independent control of key core technologies, production efficiency should also be comprehensively accelerated.

Chen Liang, who introduced the digital transformation of the chassis equipment workshop to the General Secretary, has grown into a technical backbone.

"The General Secretary is really approachable. At that time, I stood here and reported to the General Secretary the idea of intelligent transformation of our entire production line. The General Secretary listened carefully and encouraged us to continue to innovate. At that time, I was determined to realize the digital production of our entire production line," said Chen Liang, Assembly process Engineer of Xuzhou Heavy Machinery Co., Ltd. of XCMG.

For five years, Chen Liang and his colleagues solved the difficulties in the digital transformation of assembly workshops one after another by making brave efforts and ventured day and night, resulting in the production of one large-tonnage crane from seven days to two today.

Taking advantage of the "intelligent transformation and digital transformation", XCMG has increased the digitalization of production workshops from 75% to 95%, and the digitalization of key processes from 70% to 90%, becoming a national intelligent manufacturing benchmarking enterprise.

In the face of increasingly fierce industry competition, XCMG has launched the country’s first independently developed industrial Internet platform.

When the General Secretary inspected XCMG, the platform had begun to take shape and put into operation. At that time, as the person in charge of the platform, Zhang Qiliang was proud to show the platform construction results to the General Secretary.

"I reported to the General Secretary that the data of more than 400 thousand devices connected to the platform at that time were collected through the instrument independently developed based on the Beidou system," said Zhang Qiliang, General Manager of XCMG Hanyun Technology Co., Ltd..

The General Secretary requested that the industrial Internet should connect not only China, but also countries along the "the Belt and Road". After five years of development, the Hanyun platform access equipment has involved more than 2000 types, covering 80 countries and regions along the "the Belt and Road".

XCMG's main business indicators reached a record high, with its operating revenue, export revenue and net profit increased by 1.6 times, 4.3 times and 8 times. The telescopic boom wind crane with the largest tonnage exported in the world has been successfully lifted for the first time in Bosnia and Herzegovina thousands of miles away.