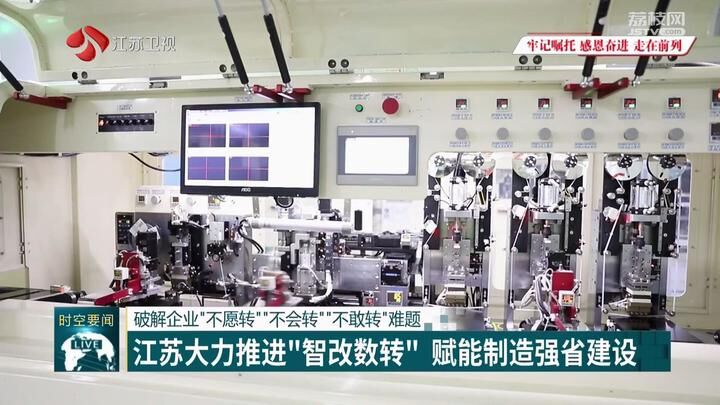

East China’s Jiangsu province has changed its traditional manufacturing model since the beginning of this year by promoting the Three Year Action Plan for Intelligent Transformation and Digital Upgrading so as to have helped many traditional manufacturing enterprises improve their efficiency and prospects.

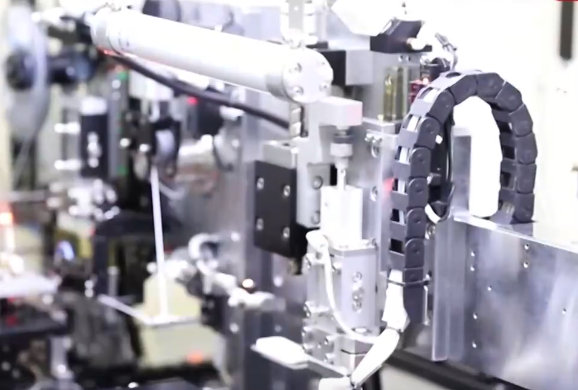

In the workshop of Jiangsu Jutai Technology Co., Ltd., seven intelligent production lines were operating at full capacity with new LCD display module products rolling off the lines. The intelligent transformation has resulted in a production and sales growth of over 40% for the enterprise this year.

“The intelligent workshop has improved our production efficiency by more than 30%, reduced production costs by 10%, and achieved a product excellence rate of 98%, which is highly favored by customers”, Zhao Shengming, General Manager of Jiangsu Jutai Technology Co., Ltd., said.

Jutai is not alone when it comes to intelligent transformation and digital upgrading.

At the end of 2021, Jiangsu released a three-year action plan for intelligent transformation and digital upgrading of the manufacturing industry by proposing to focus on 16 key advanced manufacturing clusters and 50 key industrial chains, accelerating the promotion of intelligent transformation and digital transformation of leading backbone enterprises, small and medium-sized enterprises, and industrial chains, and taking the lead in building a national demonstration zone for high-quality development of the manufacturing industry.

In response to the current situation of low intelligence level in traditional industries, Jiangsu has improved and released implementation guidelines for "intelligent transformation and digital upgrading" in 12 fields such as chemical industry, steel, and clothing. A total of nearly 100 key links, over 250 key scenarios, and over 100 enterprise cases have been sorted out for demonstration.

“We have focused on the 1650 system for hierarchical classification and promotion, giving full play to the guidance and spillover benefits of special funds, guiding various regions to carry out discount subsidies, solving the thorny problems of intelligent transformation and digital transformation, and continuously building a good ecosystem of intelligent transformation and digital upgrading”,Wang Xiaofei, Director of Industrialization and Information Technology, Provincial Department of Industry and Information Technology, said.

Since the beginning of this year, Jiangsu has issued about 4.5 billion yuan in subsidies for "intelligent transformation and digital upgrading" equipment, stimulating enterprises nearly 80 billion yuan in equipment investment and gradually improving the digital level of production equipment.

According to calculations, with the completion of various intelligent manufacturing pilot demonstration projects, enterprises in Jiangsu have recorded a production efficiency increase of over 30%, an average reduction of over 10% in production energy consumption, a reduction of over 20% in comprehensive costs, and a significant improvement in product quality and competitiveness.

As of the end of August, Jiangsu has established 3 national level digital pilot enterprises, 12 intelligent manufacturing demonstration factories, cultivated 250 provincial-level intelligent manufacturing demonstration factories, and 335 provincial-level industrial internet benchmark factories, enabling the province to complete the 14th Five Year Plan target tasks of intelligent transformation and digital upgrading more than a year ahead of schedule.