East China’s Jiangsu province has stepped up the construction of major investment projects and ensured their smooth progress through every possible effort so as to fulfill goals for social and economic development. JSBC has the story.

Polyester staple fiber is the fiber obtained from polyester re-spinning into tow after cutting, which is characterized by wear resistance and water absorption.

The 230-thousand-ton intelligent staple fiber project of Yizheng Chemical Fiber Co., Ltd. is an important part of Yizheng Chemical Fiber Polyester New Material Project.

The 1.45-billion-yuan project includes a polyester production line with an annual output of 230 thousand tons, four spunlaced non-woven polyester staple fiber production lines with an annual output of 25 thousand tons and four low melting point polyester staple fiber production lines with an annual output of 33 thousand tons, as well as utilities and auxiliary facilities.

Yizheng Chemical Fiber Co., Ltd. noted for its production of polyester staple fiber with its production and sales volume exceeded 1 million tons in 2021, making it the champion of singles in this field.

Liu Aiping, Manager of the Second Synthetic Fiber Department of Sinopec Yizheng Chemical Fiber Co., Ltd. said, "The project will further enhance the competitiveness of Yizheng chemical fiber market and make the sales of polyester staple fiber continue to lead the world."

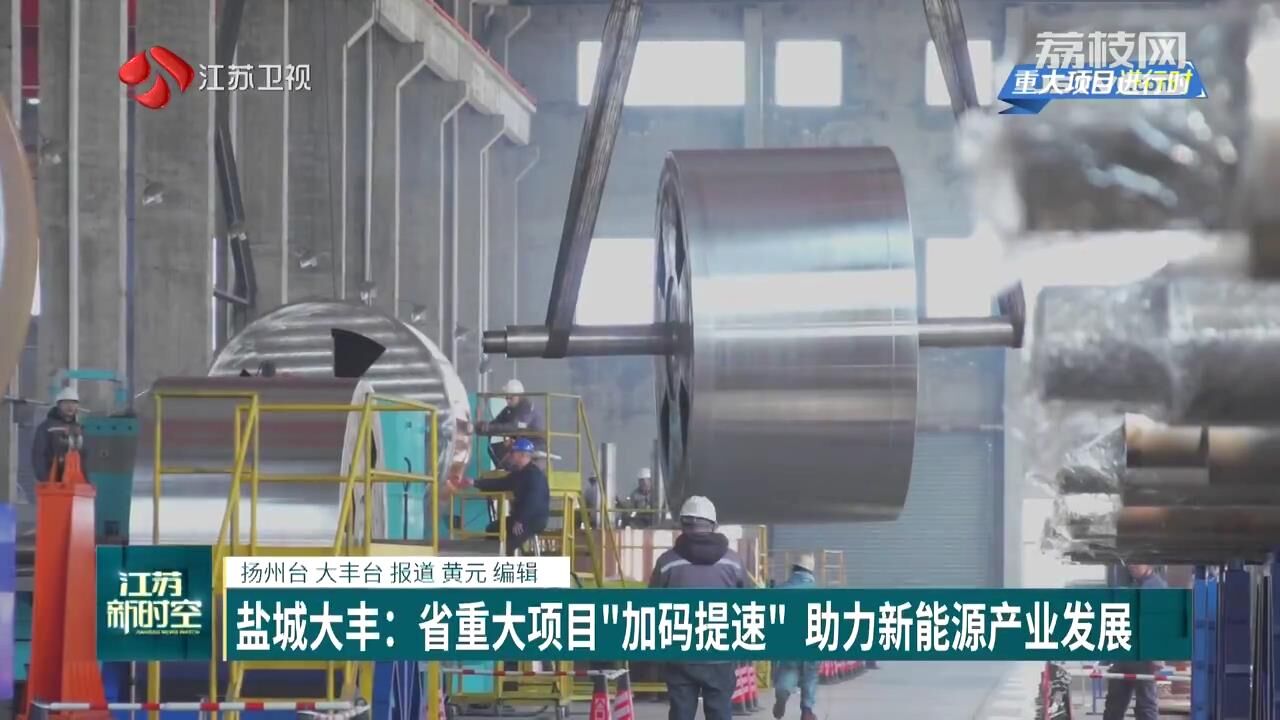

Located in Dafeng District, Yancheng City, Hongtian high-end lithium copper foil complete equipment project is one of the major projects invested by Jiangsu in 2023.

With a total investment of 3 billion yuan, the project is engaged in the production and manufacturing of new energy lithium material production equipment, copper clad plate and printed electronic circuit industry equipment, and automatic storage and logistics equipment. In the workshop, the production line is running at full power.

Chen Suxiang, Project Manager of Hongtian Technology Co., Ltd., Dafeng District, Yancheng City said, "At present, the No. 2 plant and No. 4 plant have been capped. It is expected that the equipment will be installed for trial production at the end of March. The overall project is ready to be put into production at the end of July."